Custom Apparel Printing Services in Australia

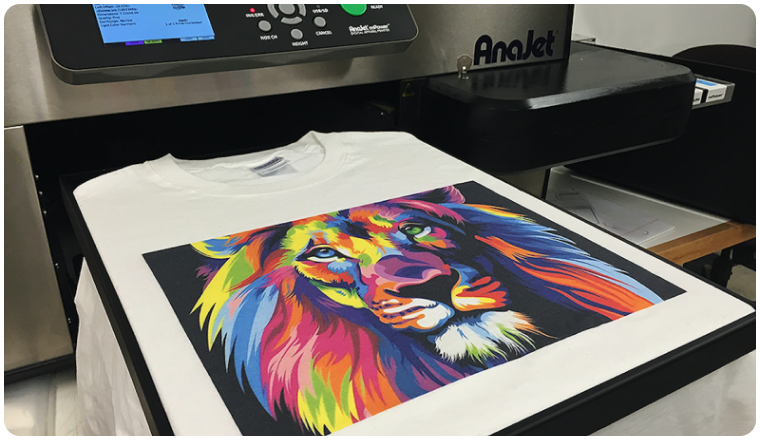

Custom apparel printing has become a cornerstone for Australian businesses looking to enhance their brand identity and connect with their audience. Whether it's bold logos on uniforms, creative designs on event merchandise, or personalised prints for corporate giveaways, the demand for custom-printed clothing has surged across industries like hospitality, construction, education, and retail. Companies are increasingly turning to custom garment printing to project professionalism, foster team spirit, and create a cohesive brand image. In Australia, where businesses value innovation and quality, custom printing services cater to diverse needs, offering options like screen printing, embroidery, and digital printing to achieve precise and lasting results.

At Garment Printing, we understand the unique requirements of Australian businesses and deliver tailored solutions that align with your branding goals. From helping startups establish their visual identity to supporting established organisations with large-scale orders, we prioritise quality, durability, and design precision in every project. Our services are not limited to just printing; we offer expert guidance on material selection, design optimisation, and printing techniques to ensure your apparel stands out. Whether you’re looking to print uniforms for your workforce or promotional apparel for events, we provide reliable, high-quality services that elevate your brand presence and leave a lasting impression.